- product service

- Municipal Water Affairs

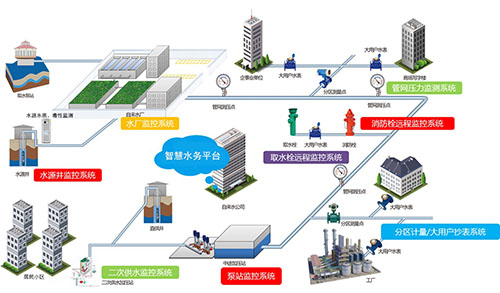

Smart Water Platform

The combination of Internet + industry has become more and more popular, and smart water services have also emerged as the times require. Smart Water uses data acquisition instruments, wireless networks, water quality and pressure gauges and other online monitoring equipment to perceive the operating status of the urban water supply and drainage system in real time, and uses a visual way to organically integrate water management departments and water supply and drainage facilities to form a "urban water Internet of Things" , And can analyze and process massive water affairs information in time,

And make corresponding processing results to assist decision-making suggestions, and manage the entire production, management and service process of the water system in a more refined and dynamic way, so as to achieve a "smart" state. Provide data analysis to ensure the scientific nature of water supply work, which can detect pipe network failures in time, improve maintenance efficiency, reduce losses, ensure water delivery and water supply quality, and achieve scientific early warning, reduce costs, and improve efficiency.

Transparent solutions for the future

Water is an irreplaceable necessities of life. At any time, water must meet the requirements of perfect water quality, and sufficient quantity and pressure supply should be guaranteed at each delivery point. Explains the safety of water supply and the paramount importance of ensuring perfect water quality. We have deep process expertise, rich experience, and mature products, systems and solutions. We adhere to the service concept of sincere cooperation with customers, and create ideal solutions that meet your needs, so that you can calmly deal with the challenges faced by the global water industry. Many challenges.

Achieve reliable water supply

Whether in big cities or in rural areas, the water supply network is a way to ensure clean water supply. In order to ensure the supply of clean water, the water needs to be sent to the water supply network through a pumping station. Water plants, pumping stations, and water treatment plants are often scattered and far apart, so they are often unattended. Therefore, the components used, including process control technology, drive, automation technology, and even process instrumentation and power supply, must be as robust and reliable as possible, and coordinate perfectly with each other.

The overall system at a glance

To know the status of the equipment used at any time, it is necessary to know the performance of the pumping station, current output and quality data. Efficient system process operation and observation are the key to achieving reliable system operation and responding to failure problems quickly and in a targeted manner. Remote control technology can connect the local pumping station to the plant-wide automation system in all directions, regardless of the geographical distance between each other.

Essential to the water environment

The sewage pipe network must not only withstand the test of heavy rainfall, but also reliably discharge domestic and industrial sewage, so it plays an important role in the water cycle. Moran has deep process expertise, rich experience, and mature products, systems and solutions, adhering to the service concept of sincere cooperation with customers, and creating an efficient pipe network design and control system for you, so that you can calmly deal with sewage discharge Many challenges.

Ensure reliable sewage treatment

Whether in large cities or in rural areas, sewage pipe networks are a way to ensure reliable sewage treatment. In most cases, sewage needs to be sent to the sewage treatment plant through a pumping station. Parts of factories, pumping stations, and treatment plants are often scattered and far apart, so they are often unattended. Therefore, the components used, including process control technology, drives, automation technology, process instrumentation and power supply, must be as robust and reliable as possible, and perfectly coordinated with each other.

Fully networked system

To keep track of the status of the equipment used at any time, it is necessary to know the pump station performance, current flow rate and water level. Efficient system process operation and observation are the key to achieving reliable system operation and responding to failure problems quickly and in a targeted manner. The remote control technology can connect the local pumping station to the plant-wide automation system in all directions without being restricted by the geographical distance between them.

Seamless processing

For widely distributed decentralized pumping stations, to improve their operational reliability, all links of the plant must be integrated into a consistent end-to-end system. Therefore, the components used must be robust, reliable and perfectly coordinated with each other-from process control technology, drive and automation engineering to power supply and full networking. In order for plant operators to keep abreast of the latest status of components, they must always be able to get an overview of all relevant information: operating messages, pump performance, current flow rate, quantity data, and analysis data. This allows efficient control and monitoring of factory processes and seamless integration into factory-wide automation systems.

Make sure the pressure is correct

The sewage pumping station plays an extremely important role in the water supply system, and is responsible for transporting sewage to the treatment plant through the sewage pipe network. Because pumping stations and treatment plants are often far apart, they are often unattended. We support factory designers and operators through a series of industry-specific products. Ultimately, consistent process management, simple user-friendly data management, and consistent end-to-end engineering between central and remote sub-factories will benefit a lot.

Reduce commissioning time through integrated plant engineering

Due to the increasingly fierce global competition, the ever-changing market demand, the increasingly stringent environmental compatibility and regulatory requirements, the pressure of international competition for plant engineering is increasing, and the water and sewage industries are no exception! Therefore, it is necessary to shorten the processing time and reduce the project cost. With our integrated engineering configuration, we will provide an optimized combination of factory design, distributed control system and equipment configuration, so as to always provide factory designers and operators with extremely high data consistency from the planning stage to the automation control and operation stage. Sex.

A comprehensive solution

Water is our number one resource. In order to improve the water quality of rivers, lakes and oceans and increase the tiny proportion of available water, efficient sewage treatment plants are essential. Especially, sewage treatment is a complex energy-intensive process, which requires all links of the treatment plant to achieve energy saving, environmental protection and simple operation and management. Whether you are planning to build a new plant or upgrade an existing plant, we will support you through hardware and software systems, comprehensive services and professional technical knowledge to keep the sewage treatment industry efficient and sustainable.

Purify water through high technology

The pollution degree of domestic sewage and industrial sewage is very different in chemical, biological and solid matter composition. Therefore, the reprocessing cost of sewage is extremely high and time-consuming. For planners and operators, the challenge is to design and operate a water treatment plant that is both economical and suitable for future development. We have a comprehensive product line and personalized solutions, ready to provide you with support.

Digitalization of the wastewater treatment industry The future sewage treatment industry has the characteristics of

intelligence and energy saving. Smart, interconnected systems help improve energy efficiency and minimize resource consumption. The main component of the LANs-Vue software platform is a digital solution that complements our mature automation and drive technology in the best way. Such solutions can help generate and provide data related to the water industry, and conduct data analysis based on facts throughout the life cycle.

Contact Morlan

- Get in touch

- telphone:021-57750057

- Email:sales@morlancontrols.com

- Address:9F, Building 1th, Jiuting center,

Songjiang District, Shanghai - Focus on us

Official WeChat

Scan the QR code and pay attention immediately

Morlan More Information

Morlan Information丨Moran Controls System (Shanghai) Co., Ltd. ICP892124722